Choosing the Right Fittings for Gas Spring Replacement

Whether you are designing a new car or simply replacing an existing piece of equipment, it is important to know how to choose the right gas spring fittings. These can be found in a variety of shapes, sizes and materials. Some are more suitable for less rugged applications while others are designed for more demanding jobs. There are also some springs that are softer than others, so it can be tricky to know which to choose.

The most basic gas spring comprises a piston, a rod and a cylinder that holds oil and pressurized nitrogen gas. The piston moves between a fully extended and fully compressed position, reducing the volume of the cylinder while providing the desired force. A gas spring is also capable of providing very low K-factors. The force produced by a gas spring is equal to the cross-sectional area of the rod. The piston also introduces a compression stroke in the cylinder.

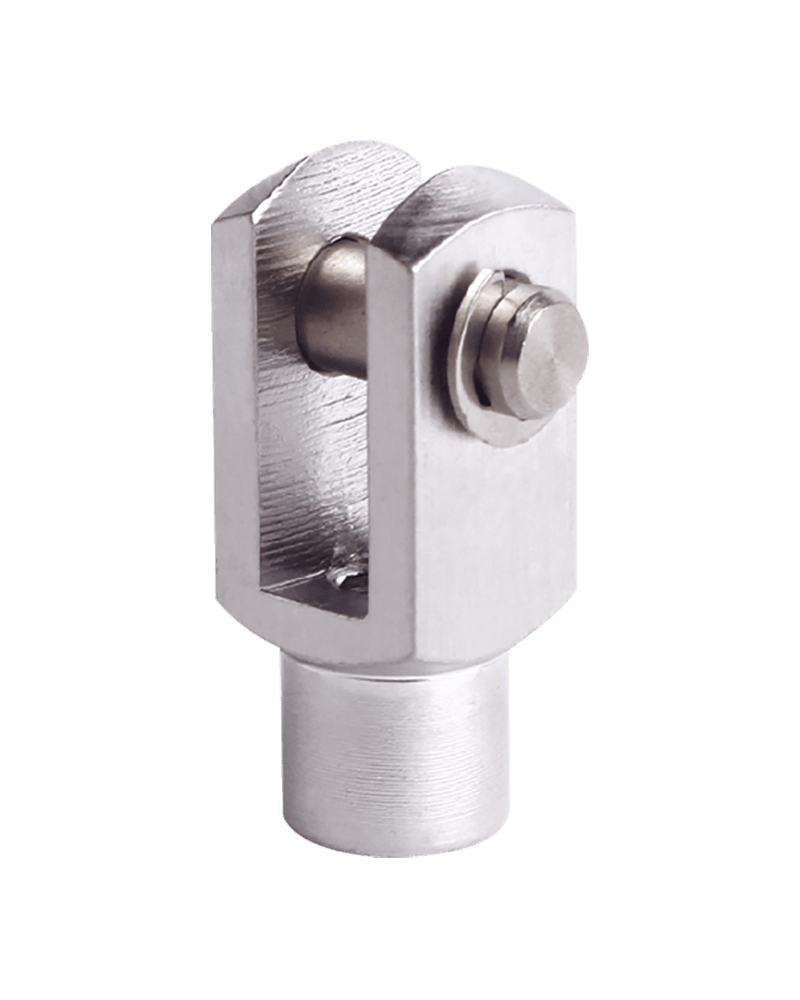

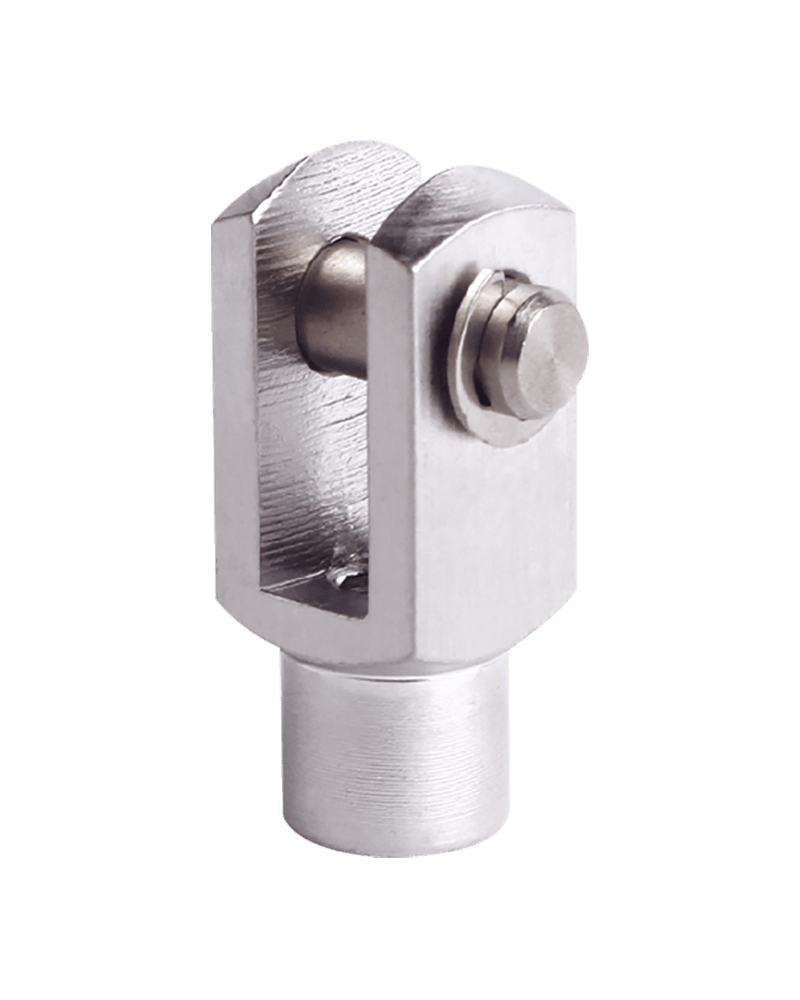

A

gas spring fitting is a two-part assembly which is screwed around the post with an included screw. In some cases, it may require more than one fitting to achieve optimal performance. There are two major types of gas spring fittings, including the clevis fork and the swivel eye joint. The latter has a M6 x 1.0 thread and is rated to support gas struts of up to 18 inches. Depending on your needs, it may also be necessary to use different types of end fittings.

The most common type of gas spring fitting is the gas strut. These are typically found in automobiles and are also found in car seats and office chairs. They are usually used to provide support to a hinged arm that is attached to pillars. They are also used for many other applications including hatches and canopies. They can be purchased from many sources, but you may want to take advantage of expert service to ensure you get the right fit.

In addition to the gas strut, there are many other types of gas spring fittings, including the ball joint, the socket joint and the clevis fork. Each is designed to provide a specific function, so it's important to know what you need before buying. Some are sturdier than others and may be necessary for more demanding jobs. They are also available in a variety of materials, including carbon steel and stainless steel. Some have been specifically designed to meet the requirements of the automotive industry. They can be purchased online or off. Some are even available with price quotes.

A gas spring fitting may be the obvious choice for many applications, but they are not without their merits. They are durable and can last for many years, making them a great choice for many applications. A number of manufacturers offer competitive prices and are able to custom-build gas springs to meet your needs. They are also available for testing, so you can see if the one you have chosen is suitable for your application.