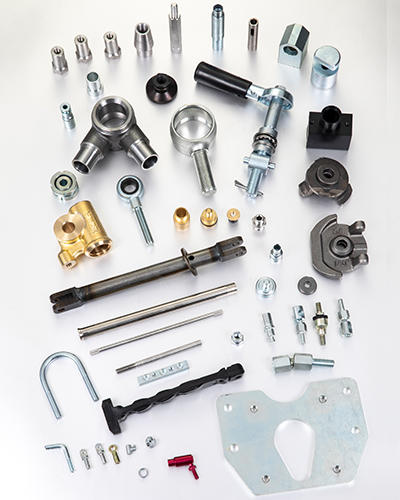

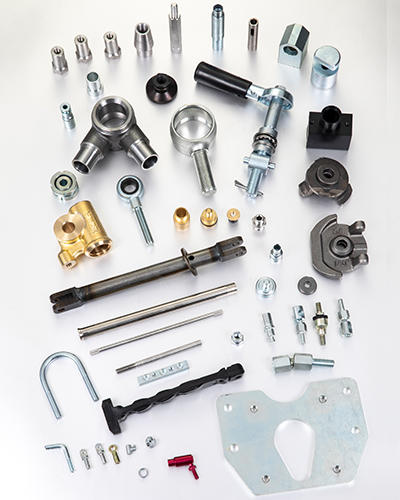

Various industries, from automotive to marine, use gas springs. These springs offer many benefits, including safety, compactness, and ability to adjust. They are also durable and have a long life span. However, it is important to keep them in good condition to ensure they last. The right accessories can help gas springs perform better. These accessories can include mounts, mounting brackets, connectors, and ball receivers.

To ensure that gas springs perform at their best, manufacturers customize them for different applications. They consider the material used in the body, as well as variables like load capacity, working temperature, and variable pressures. They also custom design the spring lengths to ensure a perfect fit.

They can be manufactured from different materials, including metal, stainless steel, and aluminum. They can also be plated with chrome, black nitride, or a combination of these materials. Stainless steel springs are resistant to corrosion and are a popular choice. They can also be customized to meet specific requirements, such as a specific load capacity or the ability to endure chemical and physical stresses.

These springs are also known as "gas shocks" because they use compressed gas to provide support for horizontally hinged items. They are typically used in awnings, automobiles, canopies, trucks, and many other applications. Some of these springs also help provide a damping effect when an external force is applied to the spring.

Gas springs come in a wide variety of shapes and sizes. They can be as small as two inches long, or as long as several feet. They can be sized to fit a wide variety of applications, from automobiles to aircraft landing gear. They have a load capacity of over 80,000 pounds. They are generally harmless, but can be a safety hazard if they are not used in an appropriate environment. They are also easy to mount, and have little to no maintenance required.

Gas springs are known for their ability to exert higher force than typical springs. This is due to their structure and design. However, they require little maintenance to operate, and the springs themselves are reliable. In addition, gas springs are durable and can withstand shocks. They are also easy to mount and control. Putting them in the wrong setting can wear them out quickly, and they are not recommended for use in corrosive environments.

These springs have many benefits over traditional springs, and they are easy to mount. However, they can only exert a small amount of force. They should be used within their design parameters, and replaced with a new spring if they are over-sprung or over-compressed. They should be drained and depressurized before re-installation.

Gas springs are generally safe, but they should be used in an appropriate environment. The pressure inside the cylinder should be below +80 degrees. In addition, they should be used in a climate that does not have extreme temperatures. Depending on the application, they can exert forces of up to 400,000 pounds.