Rod End types are used for a wide range of lubrication applications. They can provide a high level of compression or a high degree of damping, depending on the application needs. The high compression models include multiple balls to create more efficient wetting and drying abilities. The damping end is designed to reduce noise and heat buildup during high-pitched operation. All Rod End manufacturers are required to comply with OSHA regulations regarding minimum safety standards for oils and lubricants.

Most Rod End assemblies consist of one or more t/k rings. The t/k stands for Tri-axle locknut. The most common configuration uses two tri-axle locksnuts to lock the assembly into its position. However, left-hand and right-hand configurations are also available. The number of locknuts in each side of the assembly is dependent upon the type of ring used.

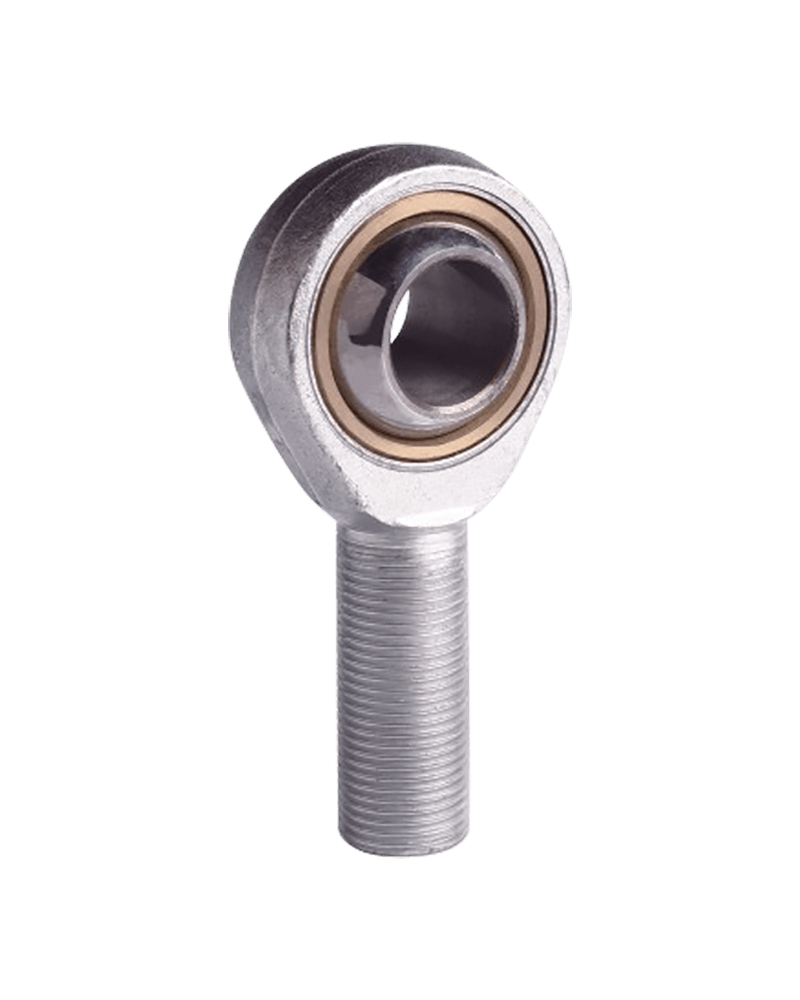

Rod-end assemblies have an inner ring and a spherical plain plate inside the assembly. The inner ring is typically made of aluminum or other metal. Typically, the outer plain plate has an epoxy coating. Some Rod-end bearing designs use an inner sphere that spreads out and presses into the cone-shaped plain plate inside the assembly in order to create the spherical plain rod ends.

Some Rod-end bearings have ball and sleeve designs. These are commonly referred to as "dinning" or "ball" Rod-end designs. The term "dinner" refers to the inner ring of the assembly. These bearings were originally developed for oil lubrication applications. The ball design provides greater flexibility for temperature ranges that are desired by drilling operators. They are generally found on drilled shafts that have a tapered end.

One popular type of Rod-end bearing is the maintenance-free rod ends or din iso 12240-4. The din iso 12240-4 was developed for use in precision machining operations and as a replacement for die casting aluminum alloy rod ends. It is primarily used for drilling holes into materials like steel, aluminum-alloy steel, and brass. These are high alloy steel tool steel shafts with a smooth surface that is durable and resistant to corrosion. The assembly process requires minimal operator involvement.

The maintenance-free rod body is constructed from high-quality white zinc plated stainless steel and are available in a variety of thicknesses. The thickness selection allows the end user to determine the specific application needed for the rod end. Often the rod end will require different core sizes to accommodate the diameter and length of the threaded rod. Some manufacturers offer a threaded rod with an adapter for use in applications where the diameter is less than one inch.

Another version of the maintenance-free and rod-end bearing is the precision Rod Bearing. The precision Rod Bearing has an optimized design that offers precise threading and larger holes. The design also provides a unique design that incorporates a ball-bearing core to eliminate backlash, a unique design that has no significant backlash, and is available in a variety of core sizes and threading widths. The precision Rod Bearing offers the most precise fit to a wide range of standard diameter and length rods. It is also available in a variety of colors.

The right rod can provide a long-lasting source of performance. With a little attention to detail, a quality rod can last a lifetime. The best way to assure a long life and optimum performance is to choose a threaded rod that is compatible with the appropriate rod body. Rods that are not compatible will degrade performance over time and require more rod maintenance to keep it performing at its best. When choosing a threaded rod, make sure the diameter and length of the rod correspond with the recommended rod-end or din iso bearings.