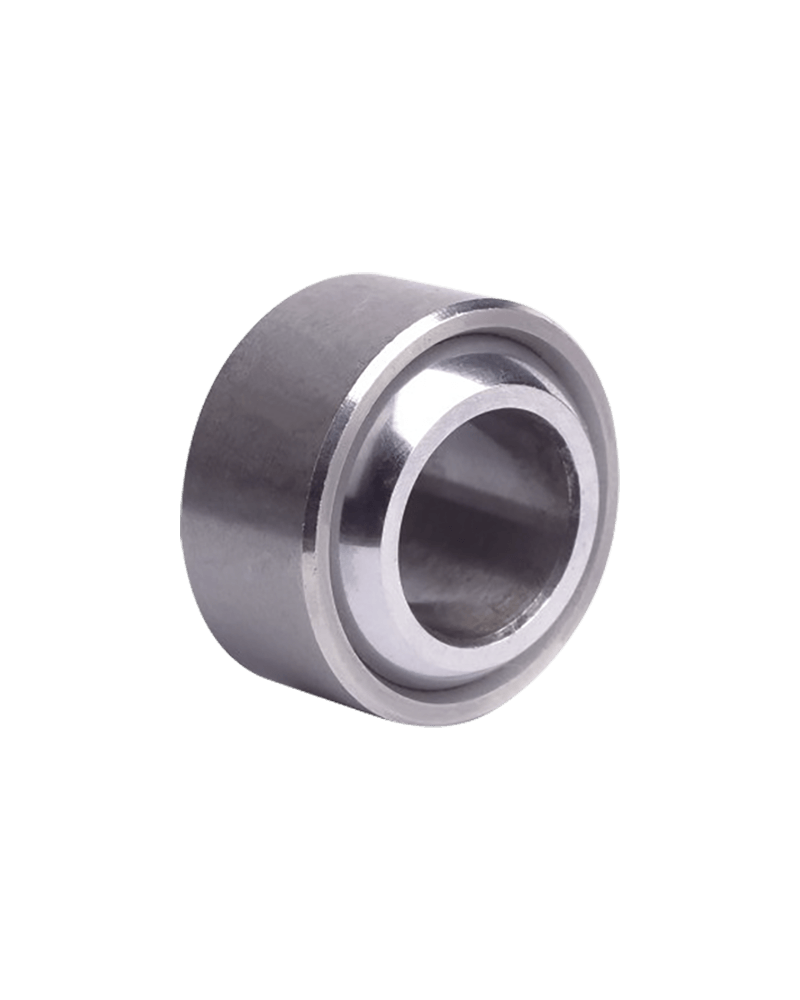

Spherical plain bearings are made of a ring on which a number of balls are mounted. They have the ability to spin and thus provide high-quality oscillation. They are used in a wide variety of bearing designs such as journals, rollers, geared shafts and casings. The inner ring in a radial plain bearing is called a sleeve or dome. The outer ring, called a cone, has the same diameter as the inner ring but a slightly smaller thickness.

The inner ring and outer ring together are called an eccentric carrier which has ball bearings. A bearing path is defined by the points where two balls roll or turn. A smooth bearing allows the balls to move smoothly within the defined bearing path. It is essential for an eccentric carrier to have a smooth inner surface because a bumpy, rougher surface will only negatively affect the operation of the bearing. Radial spherical plain bearing designs are often chosen because they provide a uniform distribution of bearing balls which results in high-quality oscillation.

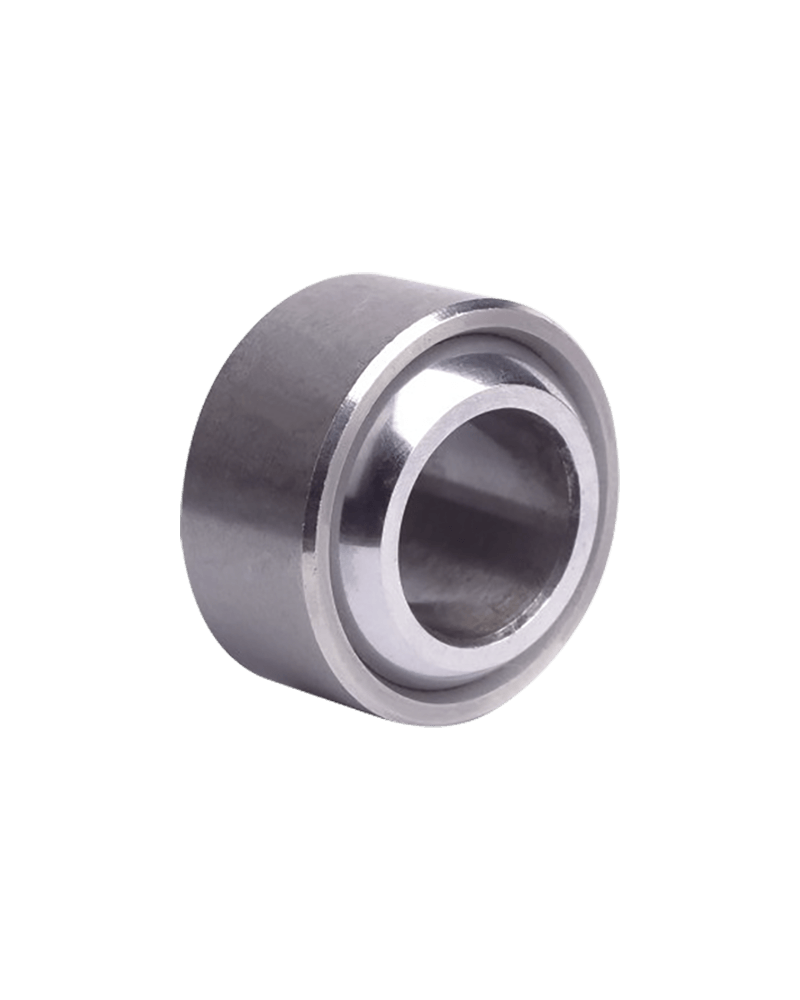

In addition to providing excellent level of performance, radial spherical plain bearings have other advantages. They require little maintenance because dirt and dust is easily wiped off. Moreover, they are more economical compared to other types of bearings because there is no lubrication process involved.

In addition, the most common material used for radial spherical plain bearings is aluminum, which is widely used in a variety of industries. These bearings come in different sizes so it is possible to install them in a wide range of machinery and equipment. For example, two standard-size spherical plain bearings can be installed in a milling machine. They also have the capability to be removed for easy cleaning and replacement according to the machinery requirements.

As you browse around the Internet, you will come across a wide variety of radial type spherical plain bearings. Most of these products are designed to meet specific requirements of various industries. Therefore, before making any purchase, it is necessary to ensure the tolerance of the bearing. The tolerance of the product refers to its ability to withstand repeated cycles of spinning at high speeds without falling down. The best way to determine the bearing's tolerance is by consulting a catalog or a supplier who deals in radial type bearings. You can also get these products online from a number of websites that sell bearings.

Some of the common radial spherical plain bearings include ball-bearing, counter-roll, bell, cylinder, tubular, sliding, and tapered. Basically, these bearings have different working principles. For instance, a ball-bearing works on the principle of centrifugal force. On the other hand, a counter-roll bearing works on the principle of sliding.

A bell bearing is a good example of a radial roller bearing. This bearing is known for its high speed and high torque. The inner ring of this bearing is attached to a small rolling drum. The roller assembly beneath the ring rolls with the help of a series of gears and rollers. Due to its design, the inner ring of the bell bearing slips easily over the outer ring.

The cylinder roller bearing is another example of radial wheeling. Cylinder roller bearings work on the principle of reciprocating motion. They can be either wound or uncoiled. Worms or chain drive devices are used to provide counter-roll action on the external surfaces of these spherical bearings. There are several other types of bearings available in the market, but if you want high performance products at affordable rates, then it would be better to consult an experienced manufacturer, rather than settle for cheaper alternatives.