Benefits of Stainless Steel Ball Joints Linkage

There are many benefits to stainless steel ball joints linkage, compared to their more traditional counterparts. In addition to offering greater corrosion resistance, stainless steel ball joints feature a threaded rod that is precision-machined for swivel in all directions. This type of ball joint is available in both Right (standard thread) and Left (reverse thread) configurations. Both types of ball joints are sold as singles or in pairs. Stainless steel ball joints linkage requires approximately 23 business days to ship.The ball joints in your car are an important part of the suspension system. If they fail, your steering and suspension systems will suffer. Not only can your steering and suspension systems be severely affected, but you may even be at risk of a serious accident. When you don't know which joint needs replacement, try looking online. You can easily find a ball joint that's right for your vehicle's model and make. If you're unsure, try using the MOOG part finder.

The ball joints used in a car's suspension system connect to the lower and upper ends of the spindle, leaving the center section open. They're used in vehicles with a front-wheel-drive configuration, as opposed to a rear-wheel-drive car. The ball joints in the suspension system allow the tire to bounce and steer during normal driving conditions. They are also used in doll joints. The ball joints are an excellent choice for a variety of applications.

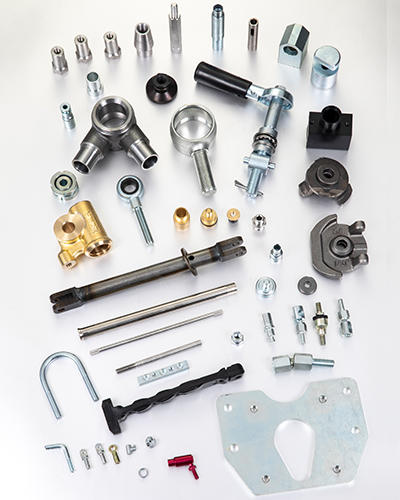

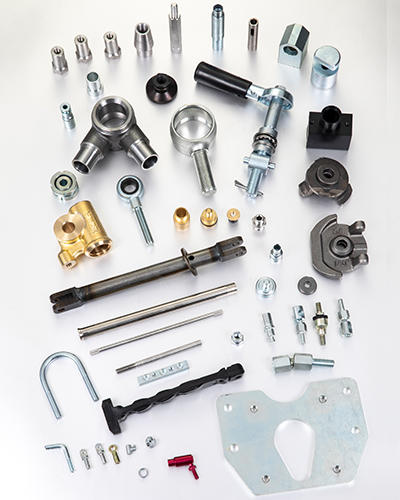

The ball joints are made to work with a variety of connecting rod materials. Typical ball joints are made of stainless steel or nickel-chrome. Other components include spherical rod ends, rubber boots, and fasteners. MCP also offers competitive pricing on any connecting rod, ranging from 10-32 through 1.25-12. A few companies even manufacture spherical rod ends. Whether you need a ball joint for a single-spherical rod or need a complete linkage, MCP can provide a custom assembly.

If you've been ignoring your car's ball joints, you're not alone. The ball joints in your car may be suffering from premature failure. Worn ball joints can cause uneven wear on your tyres. You may even experience steering vibration or unusual noises. If you've experienced any of these issues, it's time to have them replaced. It's worth it to protect your car's suspension from unnecessary damage.

A ball joint is part of your car's front suspension system. It connects the steering knuckles and control arms to the steering spindles. It also allows for independent movement of the wheels. Its purpose is to maximize tire contact with the road. The ball joint is made up of a ball and a socket, and is very similar to the hip joint in a human body. It helps to keep the car in the right position and provides smooth movement in the suspension system.

A jack should be used to lift the car to check for runout in the steering knuckle. Alternatively, you can use a dial indicator to measure axial runout in the steering knuckle. A wheel can be used to check lateral runout as well. A wheel can also be used to check lateral runout.

Tire wear and tire life will increase if you do not fix your car's steering linkage. Not only will it cause excessive tire wear, but broken steering linkage can also become a liability issue. If you have a car accident, a broken ball joint can lead to loss of control and an accident. This is why it is critical to take the proper steps for steering linkage maintenance. A professional alignment technician will inspect and repair the steering linkage parts to ensure the vehicle's safety.