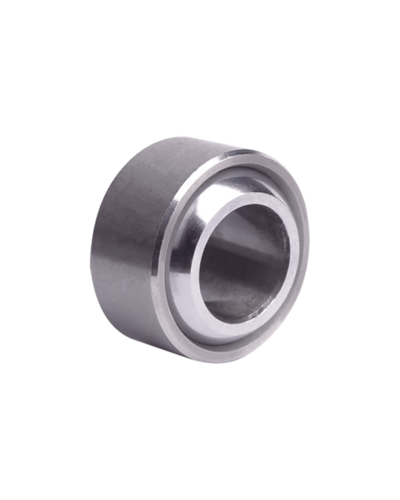

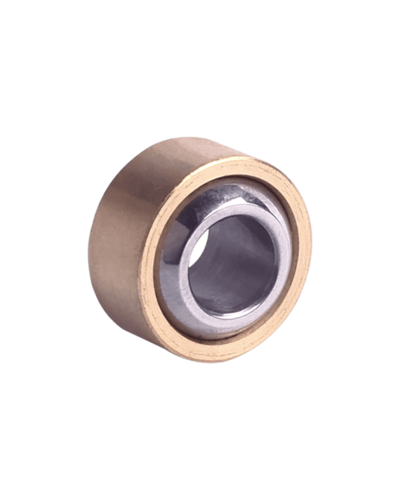

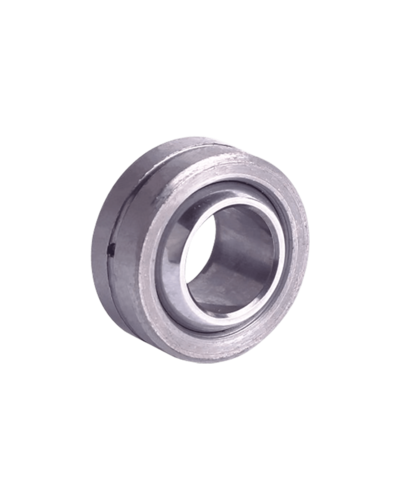

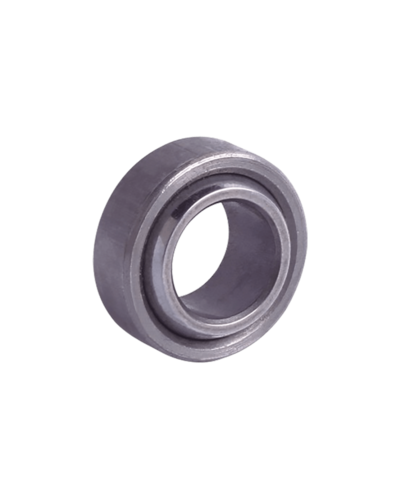

Radial spherical plain bearings, also known as spherical plain bearings or spherical plain bushings, are mechanical components used to accommodate rotational and oscillating movements between two components. They are designed to handle both radial and axial loads while allowing for misalignment and angular movement.

The key features and characteristics of radial spherical plain bearings are as follows:

Spherical Inner Ring and Outer Ring: Radial spherical plain bearings consist of an inner ring with a spherical sliding surface and an outer ring with a matching spherical sliding surface. The inner and outer rings are typically made of steel and have a precision-ground surface for smooth movement.

Sliding Surface: The sliding surfaces of the inner and outer rings are usually treated with a self-lubricating material, such as PTFE (polytetrafluoroethylene) or a combination of PTFE and other materials. This reduces friction, minimizes wear, and allows for maintenance-free operation.

Maintenance-Free Operation: Radial spherical plain bearings are often designed for maintenance-free operation, thanks to the self-lubricating properties of the sliding surfaces. This reduces the need for additional lubrication and simplifies maintenance requirements.

Misalignment Compensation: These bearings can accommodate misalignment between the mating components. They can handle angular misalignment, which arises from shaft deflection, manufacturing tolerances, or mounting errors. This feature helps to distribute loads evenly and prolong the bearing's life.

Load Capacity and Durability: Radial spherical plain bearings are capable of carrying both radial and axial loads. They are designed to withstand high loads and offer excellent durability and resistance to wear and fatigue.

Wide Range of Sizes and Variants: Radial spherical plain bearings are available in a wide range of sizes, designs, and variants to suit various applications. They come in different series and configurations, such as maintenance-free, sealed, or steel-on-steel variations, to meet specific performance and environmental requirements.

Application Areas: Radial spherical plain bearings find applications in numerous industries and machinery, including automotive, construction, agriculture, mining, and general industrial equipment. They are used in various components and systems such as suspension systems, hydraulic cylinders, steering mechanisms, linkages, and articulated joints.

Radial spherical plain bearings play a critical role in allowing smooth and controlled movement between components while withstanding loads and compensating for misalignment. They provide reliable performance and longevity in a wide range of applications and contribute to efficient and durable mechanical systems.

When choosing radial spherical plain bearings for a specific application, several factors should be considered to ensure optimal performance and suitability. Here are some key factors to consider:

Load Requirements: Determine the magnitude and type of loads the bearing will experience, including radial, axial, and moment loads. Consider both static and dynamic loads, as well as peak loads or intermittent loads. Choose a bearing with a load capacity that exceeds the expected loads to ensure safe and reliable operation.

Operating Conditions: Consider the operating conditions in which the bearing will be used, including temperature, humidity, contaminants, and potential exposure to water, chemicals, or extreme environments. Choose a bearing that is designed to withstand the specific conditions encountered in the application.

Misalignment Compensation: Assess the degree of misalignment that the bearing will need to accommodate. Consider angular misalignment, as well as potential shaft deflection or mounting errors. Choose a bearing with sufficient misalignment capabilities to ensure proper load distribution and minimize stress on the bearing and surrounding components.

Lubrication Requirements: Determine whether the application requires a bearing that requires regular lubrication or one that is maintenance-free. Consider factors such as accessibility for lubrication, operating conditions, and the desired level of maintenance. Choose a bearing with the appropriate lubrication option, such as self-lubricating or with lubrication fittings, based on the application requirements.

Bearing Design and Configuration: Radial spherical plain bearings come in various designs and configurations, including different series and materials. Consider factors such as space constraints, shaft size, mounting options, and compatibility with mating components. Choose a bearing that fits the application's dimensional requirements and offers the desired performance characteristics.

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More