Gas springs, also known as gas struts, are used in a wide range of applications to provide controlled and reliable movement. They consist of a cylinder filled with pressurized gas and a piston that moves in response to changes in pressure. Gas springs are commonly used in automotive, aerospace, medical, and industrial equipment, and are an essential component in many types of machinery and equipment.

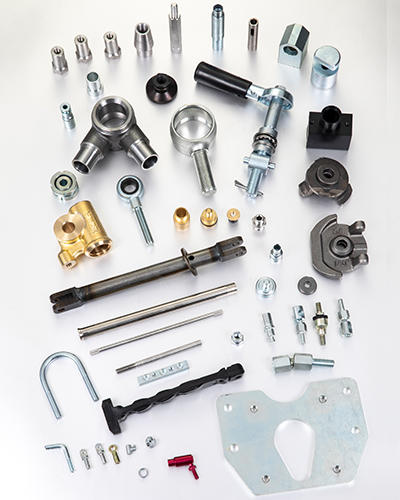

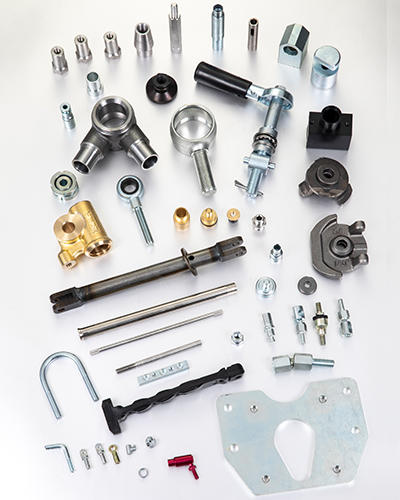

Fittings are an essential part of any gas spring installation, as they connect the gas spring to other components of the system, such as mounting brackets or connecting rods. There are several types of fittings available

for gas springs, each designed for specific applications and usage scenarios.

Eye fittings: These fittings are the most common type of gas spring fitting and are used in applications where the gas spring needs to be mounted to a bracket or other component. Eye fittings are typically made from steel or stainless steel and are available in a range of sizes to suit different gas spring diameters.

Clevis fittings: These fittings are similar to eye fittings but feature a U-shaped design that allows for greater range of motion. Clevis fittings are commonly used in applications where the gas spring needs to pivot or rotate, such as on hinged doors or lids.

Ball joint fittings: These fittings feature a ball and socket design that allows for even greater range of motion than clevis fittings. Ball joint fittings are commonly used in applications where the gas spring needs to operate at an angle, such as on tilt trays or hinged covers.

Threaded fittings: These fittings feature a threaded design that allows for easy installation and removal of the gas spring. Threaded fittings are commonly used in applications where the gas spring needs to be quickly and easily removed for maintenance or repair.

Stud fittings: These fittings feature a threaded stud that protrudes from the end of the gas spring and is used to connect the gas spring to other components. Stud fittings are commonly used in applications where the gas spring needs to be directly mounted to a frame or other fixed component.

Brackets: Brackets are used to mount the gas spring to other components or structures, such as a vehicle body or a machine frame. Brackets are available in a range of sizes and designs to suit different gas spring applications, and are commonly made from steel or stainless steel for durability.

When selecting fittings for a gas spring installation, it is important to consider the specific requirements of the application. Factors to consider include the size and weight of the component being moved, the required range of motion, and the operating environment (such as temperature and humidity). In addition, it is important to select fittings that are compatible with the gas spring and other components of the system, to ensure reliable and safe operation.