Why Choose Radial Spherical Plain Bearings for Your Application?

2025-08-28

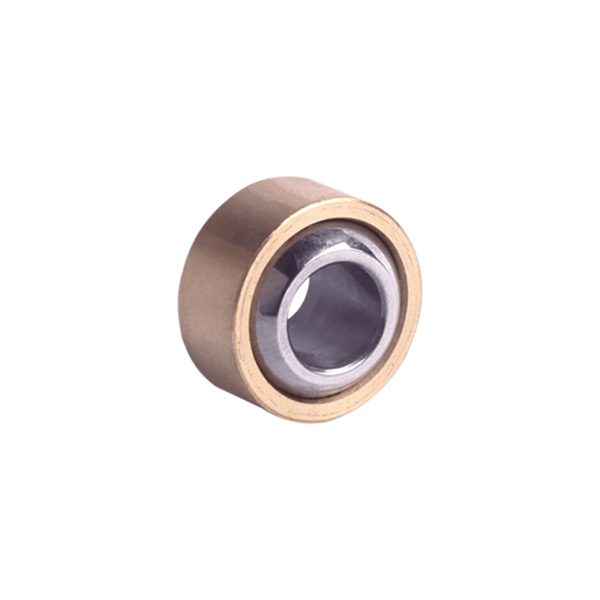

When engineers and purchasing managers seek reliable solutions for heavy-duty load transmission and misalignment compensation, Radial Spherical Plain Bearings often emerge as the ideal choice. These components are essential in applications where oscillating motion, high load capacity, and long service life are required. Their unique construction allows them to function effectively under conditions where traditional rolling bearings may not provide the same performance or durability.

In my two decades of experience in bearing applications, I have seen many industries—construction machinery, hydraulic systems, agricultural equipment, and transportation—rely heavily on Radial Spherical Plain Bearings to reduce wear and extend operational life. The following sections explain their functions, technical parameters, advantages, and frequently asked questions to help you make a well-informed selection.

What Are Radial Spherical Plain Bearings?

Radial Spherical Plain Bearings are mechanical components designed to accommodate radial loads and allow angular misalignment between connected parts. Unlike rolling element bearings that use balls or rollers, these bearings use a spherical sliding contact surface between the inner and outer rings.

This design offers excellent resistance to shock loads and the ability to perform under poor lubrication conditions. The sliding contact can be made from hardened steel, steel-on-steel combinations, or self-lubricating materials such as PTFE composites.

Key Functions of Radial Spherical Plain Bearings

-

Absorb High Radial Loads: Specially engineered to manage heavy static and dynamic radial forces.

-

Allow Angular Movement: Their spherical design compensates for misalignment between shaft and housing.

-

Durability in Harsh Environments: Resistant to dust, dirt, vibration, and shock loads.

Product Parameters of Radial Spherical Plain Bearings

At Ningbo Dongzhou Transmission Co., Ltd., we manufacture and supply a complete range of Radial Spherical Plain Bearings. Below are some general parameters to guide your selection.

Dimensional Range (Typical)

-

Bore Diameter (d): 6 mm – 800 mm

-

Outer Diameter (D): 16 mm – 1,000 mm

-

Width (B): 7 mm – 500 mm

Load Capacity

-

Dynamic Load Rating (C): Up to 3,000 kN

-

Static Load Rating (C₀): Up to 6,000 kN

Technical Specifications Table

| Parameter | Value Range | Notes |

|---|---|---|

| Bore Diameter (d) | 6 mm – 800 mm | Customized sizes available |

| Outer Diameter (D) | 16 mm – 1000 mm | Standard & non-standard designs |

| Width (B) | 7 mm – 500 mm | Dependent on application |

| Dynamic Load Rating (C) | Up to 3000 kN | Varies by size and design |

| Static Load Rating (C₀) | Up to 6000 kN | Ensures reliability under peak loads |

| Operating Temperature | -40 °C to +200 °C | Depends on material & lubrication |

| Material Options | GCr15, 100Cr6, PTFE composites, bronze | Multiple configurations available |

| Lubrication Type | Grease-lubricated or self-lubricating | Customer-specific choice |

Advantages of Choosing Our Radial Spherical Plain Bearings

-

High Load Capacity: Designed for demanding conditions in construction and heavy industries.

-

Misalignment Compensation: Angular movement allows flexibility in shaft-to-housing positioning.

-

Durable Surface Treatments: Corrosion-resistant coatings extend product life.

-

Low Friction Options: Self-lubricating liners minimize maintenance.

-

Custom Engineering: Ningbo Dongzhou Transmission Co., Ltd. provides tailored solutions.

FAQ: Radial Spherical Plain Bearings

Q1: What is the main function of Radial Spherical Plain Bearings?

A1: Their primary role is to support high radial loads while allowing angular misalignment between connected components. They provide durability and flexibility, particularly in oscillating or pivoting applications.

Q2: How do Radial Spherical Plain Bearings differ from rolling element bearings?

A2: Unlike rolling bearings that rely on balls or rollers, Radial Spherical Plain Bearings have sliding contact surfaces. This allows them to handle higher loads, shock absorption, and angular misalignment more effectively.

Q3: What materials are used in Radial Spherical Plain Bearings?

A3: Common materials include hardened steel (GCr15, 100Cr6), carbon steel with protective coatings, and liners made from PTFE composites, steel-on-steel, or bronze, depending on the lubrication requirements.

Q4: Are these bearings maintenance-free?

A4: Both options are available. Steel-on-steel bearings require periodic lubrication, while PTFE-lined bearings are self-lubricating and virtually maintenance-free, making them suitable for hard-to-reach installations.

Conclusion

Radial Spherical Plain Bearings are essential in industries where reliability, high load capacity, and misalignment adjustment are crucial. With options ranging from maintenance-free PTFE-lined designs to high-strength steel-on-steel versions, these bearings offer versatile solutions for modern machinery.

For high-quality Radial Spherical Plain Bearings designed and manufactured with precision, Ningbo Dongzhou Transmission Co., Ltd. is your trusted partner. Our expertise, advanced production capabilities, and commitment to customer satisfaction ensure that you receive products tailored to your needs.

Contact us today to learn more about our complete range of Radial Spherical Plain Bearings and customized solutions.