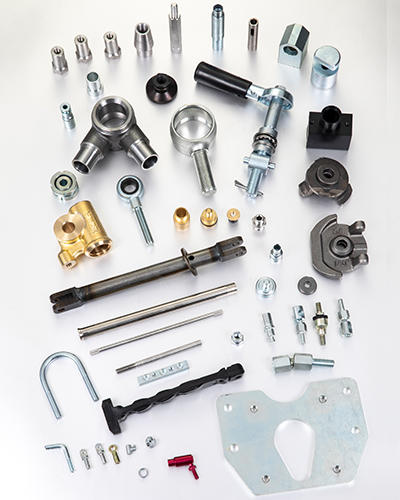

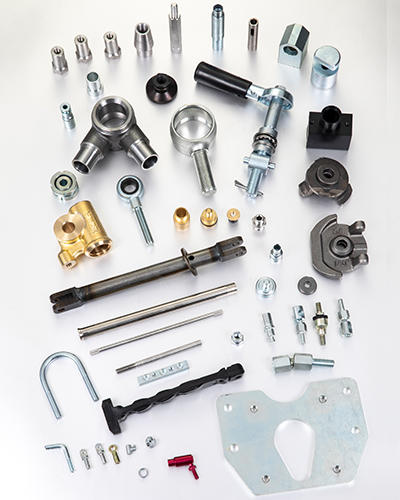

Whether you need to replace or repair a gas spring, there are many available accessories that can help you get the most out of your investment. Some of the more common

gas spring accessories include stainless steel socket end fittings, nylon socket end fittings, and O-rings. These gas spring accessories are made to fit a variety of applications and make it easy to maintain your springs.

One common gas spring accessory is a locking gas spring. These gas springs lock in place after a full extension. They are designed to provide a controlled rate of extension, making them useful in applications such as car hoods and furniture. It's important to keep your gas springs in good condition, or they could wear out quickly. If you want to prevent your spring from deteriorating, be sure to regularly clean and drain the gas.

Another common gas spring accessory is a guide and seal package. This gas spring accessory is made of a plastic composite that provides a bearing surface for the rod. The package also seals the tube end of the spring. It keeps the gas from escaping and prevents the rod from damaging the piston during extension. It also protects the rod from damage during compression.

Another gas spring accessory is a movable end stop. This accessory can decrease the amount of gas inside the spring, which can help reduce the overall pressure. It can also be used to lock the rod into place after a full extension. It is important to note that a movable end stop can also increase the pressure inside the spring.

Gas springs are extremely important for a number of applications. They're used in automobiles, furniture, and even tanning beds. They also offer a wide range of benefits, including shock absorption and easy adjustment. Unlike mechanical springs, they require little maintenance. They're also extremely durable, and they don't wear out as quickly as other types of springs.

Depending on the application, gas springs can exert forces from 2500 pounds to 400,000 pounds. The springs can be manufactured in various sizes, including small and large cylinders. In addition to the spring's size, manufacturers also need to consider the pressures and velocities that the spring is expected to operate under. They can also customize the spring's features.

For example, a gas spring's piston assembly is made of zinc or aluminum, and its metering is designed to control the rate of compression. Manufacturers can also coat the spring material with black nitride or chrome plating. The internal surface of the gas spring tube is also important, as it is crucial for the spring's longevity and burst pressure performance.

Gas springs can also be used in defense applications, and manufacturers must be able to produce their products in military-grade materials. They must also be FDA-compliant. These types of springs are also used in the food service industry. It's important to remember that gas springs should not be used in corrosive environments.